Leaders of Polish higher education 2025

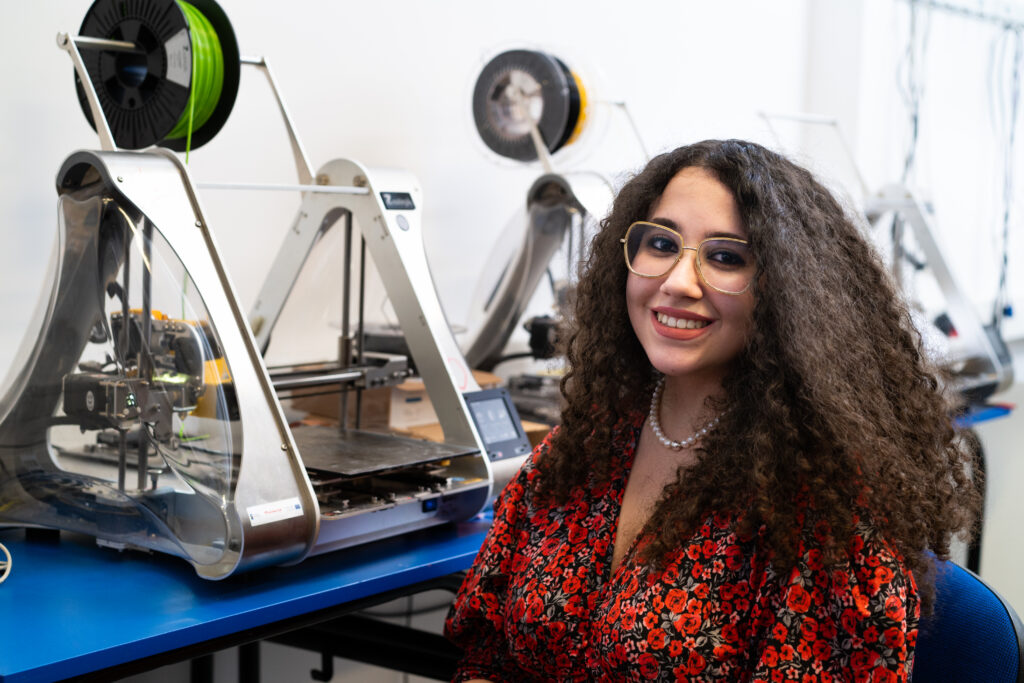

At the Polish-Japanese Academy of Information Technology, we focus on modernity and innovation. We know how important it is to have access to the latest technologies in education. That's why our laboratories are equipped with advanced equipment that allows students to carry out challenging projects and acquire practical skills.

One of the key elements of our equipment are 3D printers, available in the Print Lab. Such printers really have applications in many fields, and students can find out for themselves by experimenting with modeling and printing. Most of the projects carried out in the Lab are done in FDM (Fused Deposition Modeling) technology, which is the most widely used incremental method in the world. Depending on the educational path chosen, students can learn modeling in a variety of programs, including SolidWorks, Fusion360 and Maya.

For years, we have been systematically equipping our laboratories with modern tools and equipment. As a result, we have an extensive collection of 3D printers, each with its own unique application. As a result, some of the models are already years old. Nevertheless, they still bravely serve us for teaching purposes. They are regularly serviced and used in projects carried out by Academic Student Clubs or in exhibition projects, among others. At the same time, we place great emphasis on the continuous development and modernization of our laboratories. We systematically supply them with technological innovations, which we add to our growing collection. This allows us to ensure that as many students and employees as possible have easy access to the latest technologies.

Below is our current list of 3D printers that serve students and employees PJAIT.

Specifications: This industrial-grade 3D printer offers full-color ColorJet (CJP) printing. It stands out for its large working area and high productivity. With full CMYK technology, it guarantees the production of realistic models at the highest resolution. ColorJet printing technology is an additive manufacturing technology consisting of two main components: a core material (based on gypsum) and a binder. The core material is spread in thin layers on the working platform using a roller. After each layer is spread, the colored binder is selectively applied from inkjet print heads, which hardens the core. The working platform lowers to allow each successive layer to be spread and printed, resulting in a full-color three-dimensional model. CJP technology eliminates the need to build support elements, allowing multiple models to be printed simultaneously without the risk of collisions.

Product link: ProJet CJP 660Pro

Specification: This industrial-grade resin printer is designed for precision and versatility. It can print both rigid and elastomeric parts with CAD-compliant accuracy, offering excellent surface finish and high-quality edges for functional testing. The printer supports Ultra High Definition mode, achieving detail resolution of up to 300 microns. Ideal for applications such as conceptual modeling, functional prototyping and medical applications requiring biocompatibility.

Product link: ProJet MJP 2500

Specification: the latest acquisition at PJAIT, this 3D printer is a true rarity on the market. Equipped with five print heads, it offers unparalleled printing capabilities. Its most important feature is the ability to print truly huge projects. It allows fast multi-material printing, combining different materials like TPU with PCCF or PLA with PETG. A segmented heating table with 16 individually controlled tiles prevents thermal distortion. The Original Prusa XL offers great flexibility and print quality while producing minimal waste.

Product Link: Original Prusa XL

Specification: This is a 3D printer made in Poland, working with FDM technology. The device has interchangeable heads, making it multifunctional. It can be used for 3D printing, CNC milling and laser engraving.

Product Link: Zmorph SX 2.0

Specification: This printer is built according to CoreXY kinematics, which allows it to achieve print speeds of up to 500 mm/sec. It is equipped with AMS, or box, which allows it to change filament automatically. It has an enclosed workspace, an efficient cooling system and a charcoal filter, which enable it to work with advanced filaments.

Product Link: BambuLab P1S

Specification: It is a versatile, modular 3D printer that combines 3D printing, laser engraving and CNC milling functions into one machine. The modular design allows users to easily switch between functions and expand the machine with various add-ons, including a dual extrusion module and a 10-watt laser module. Its key features include a metal construction that provides durability and stability, and a motion control algorithm that improves print quality by reducing gaps and cracks.

Product Link: Snapmaker 2.0

Contact the Recruitment Department to get answers to all your questions.

enrolment @pja.edu.pl